| 1 |

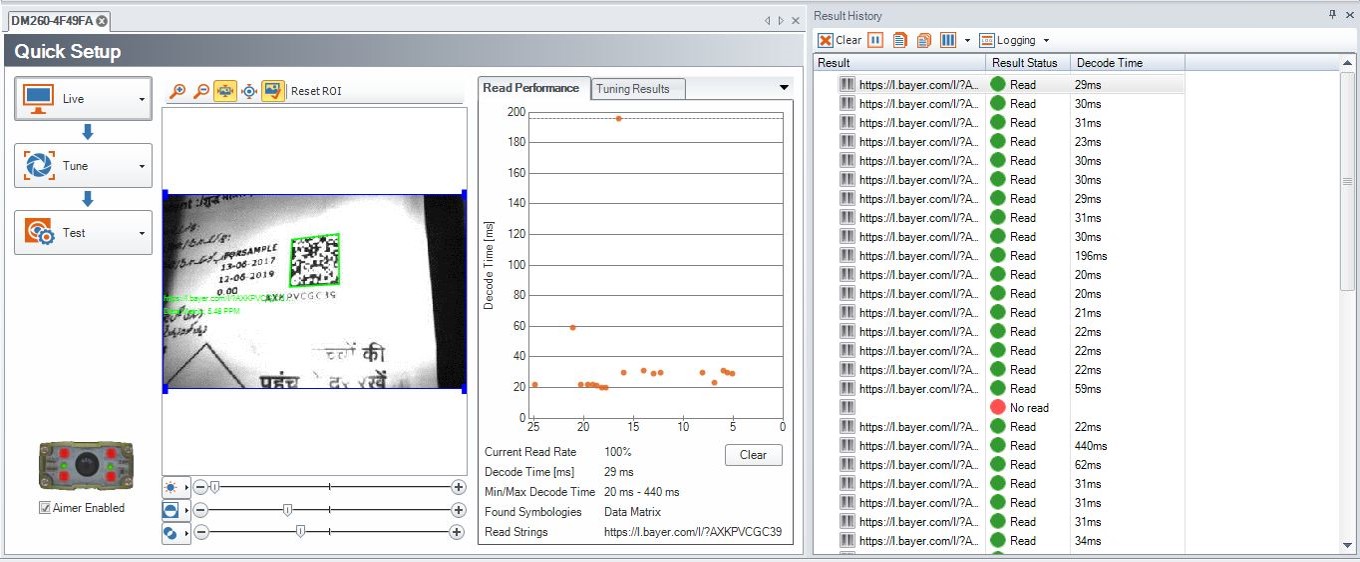

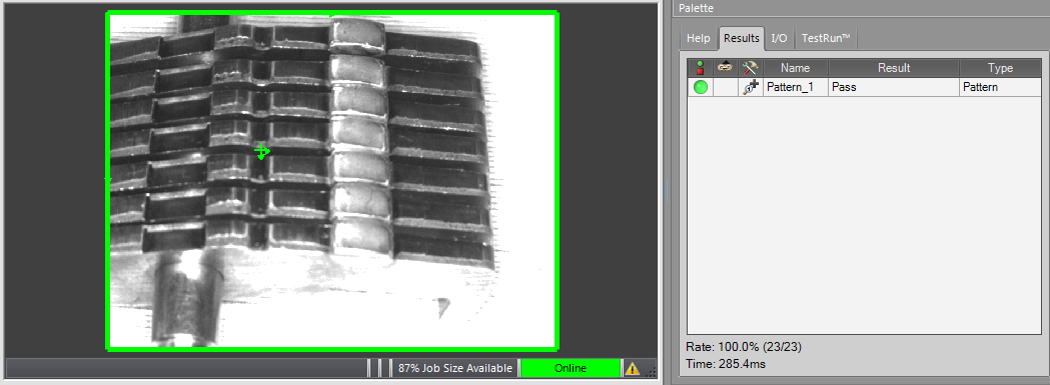

A high-speed advanced platform that runs the latest proprietary Cognex algorithms for decoding both 1-D and 2-D symbologies |

| 2 |

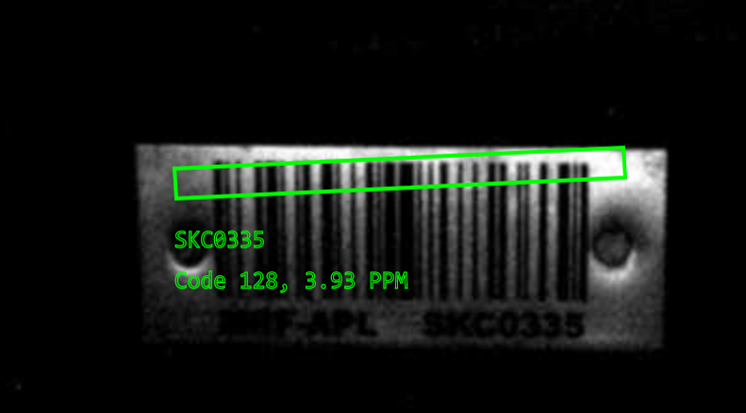

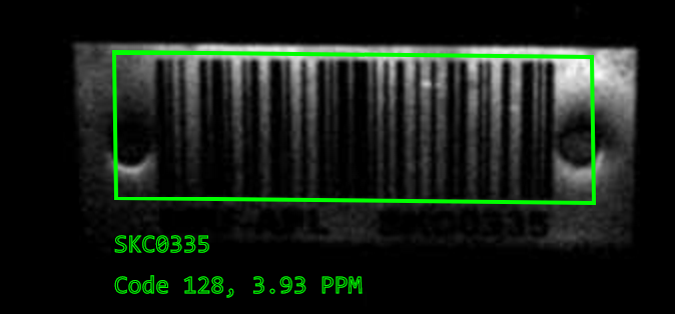

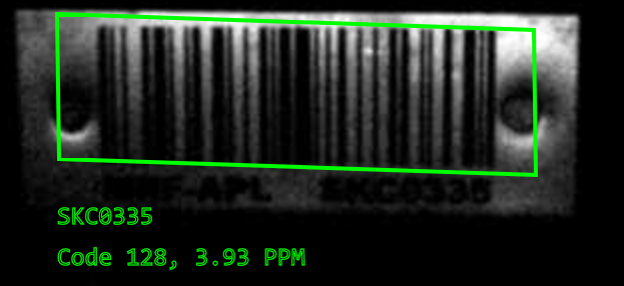

1DMax with Hotbars II provides high read rates on 1-D barcodes, even those that may be damaged or distorted |

| 3 |

Hotbars II delivers "barcode stitching" technology and 0.8 ppm (pixels per module) decoding speed to help you solve applications with fewer readers and less complexity |

| 4 |

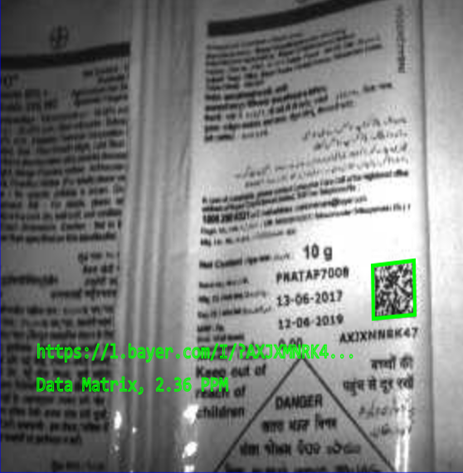

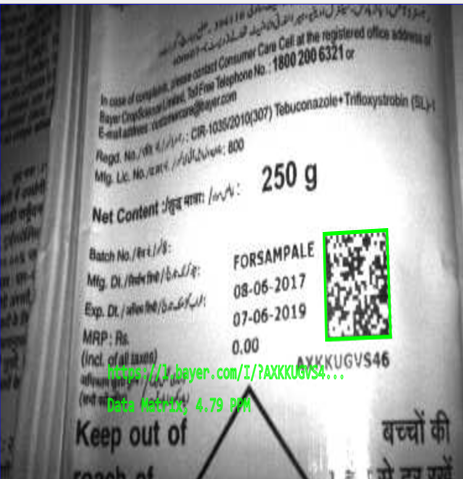

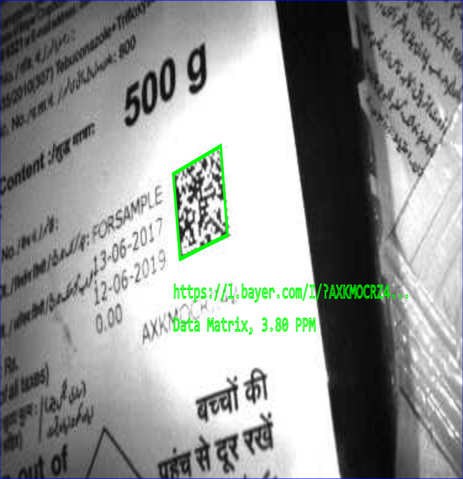

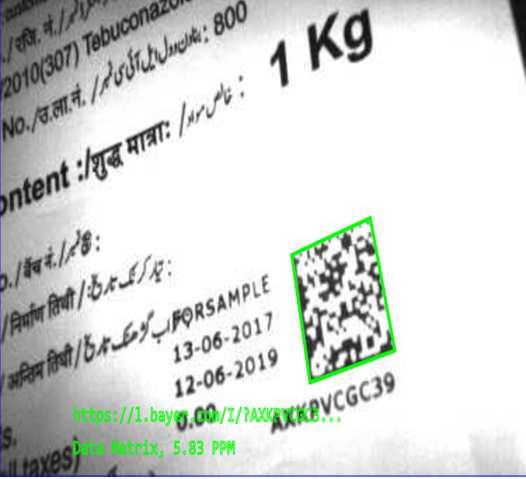

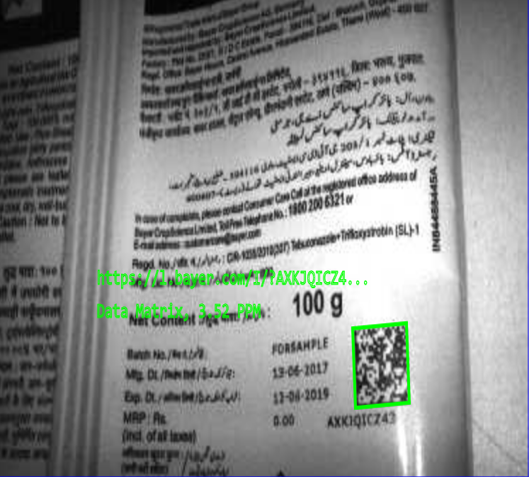

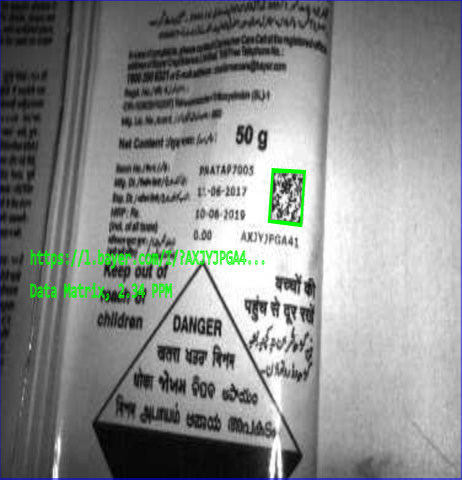

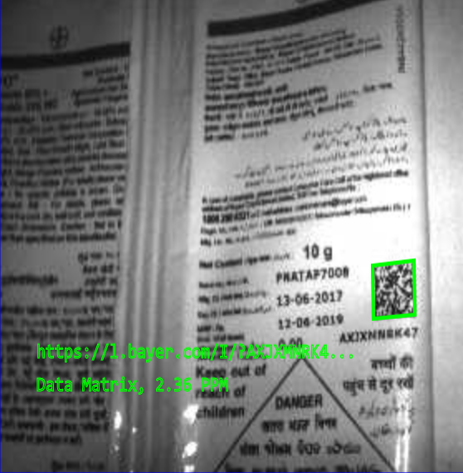

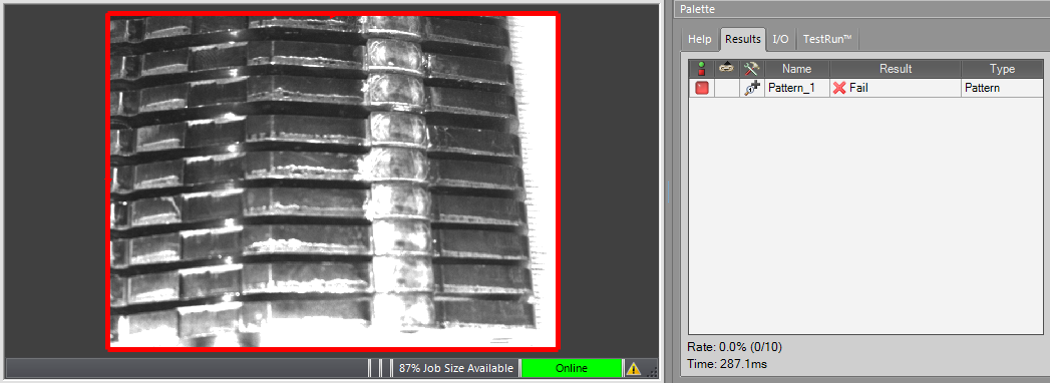

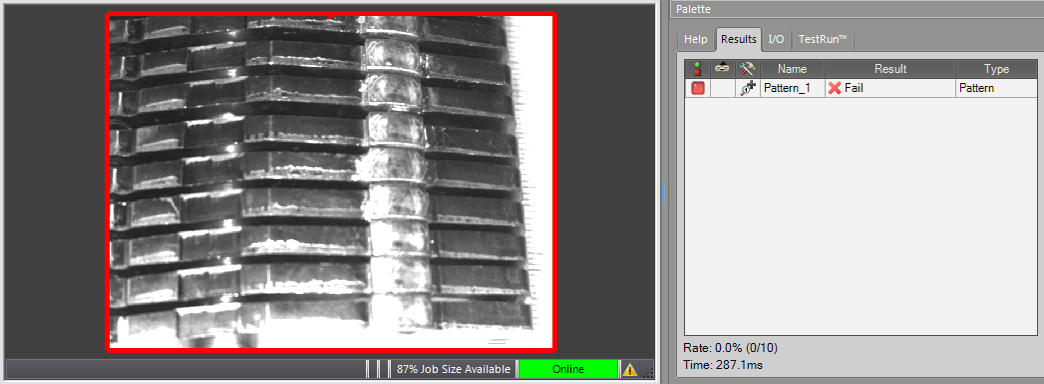

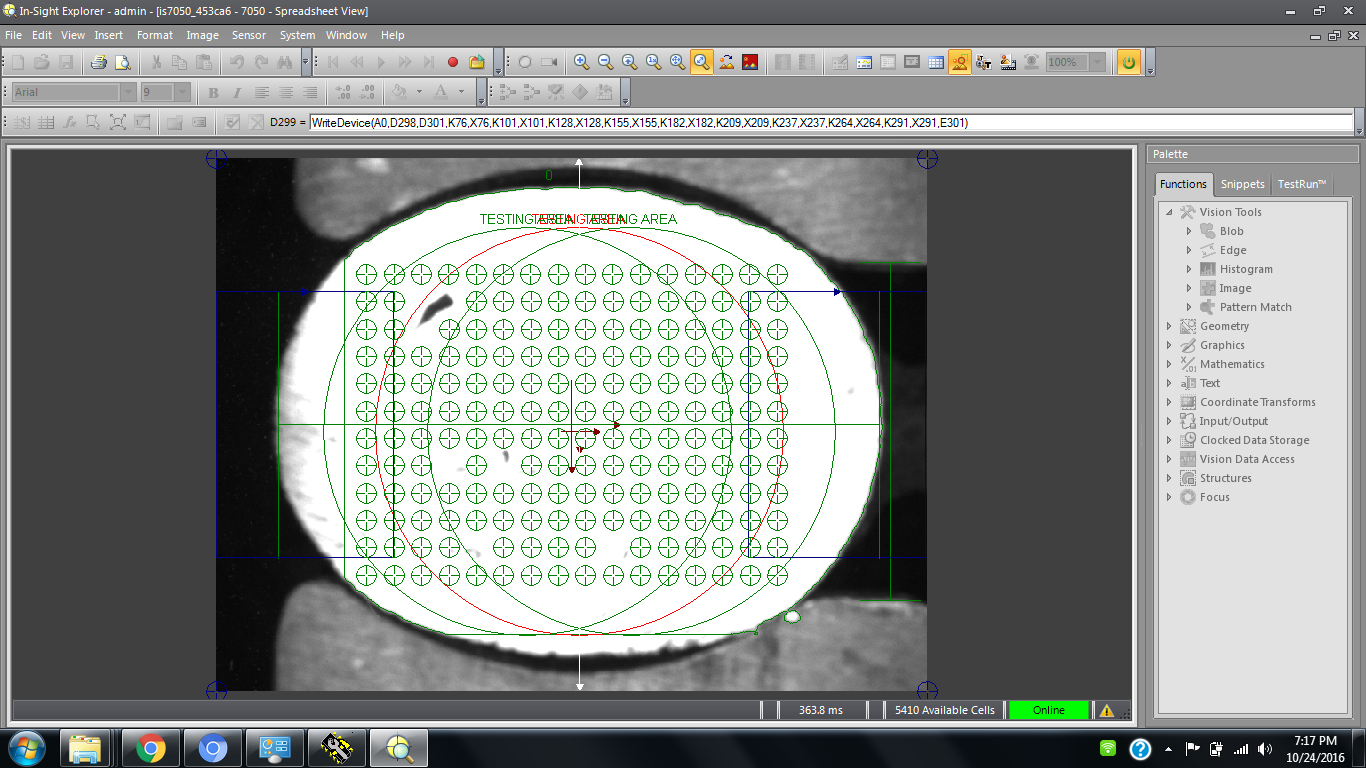

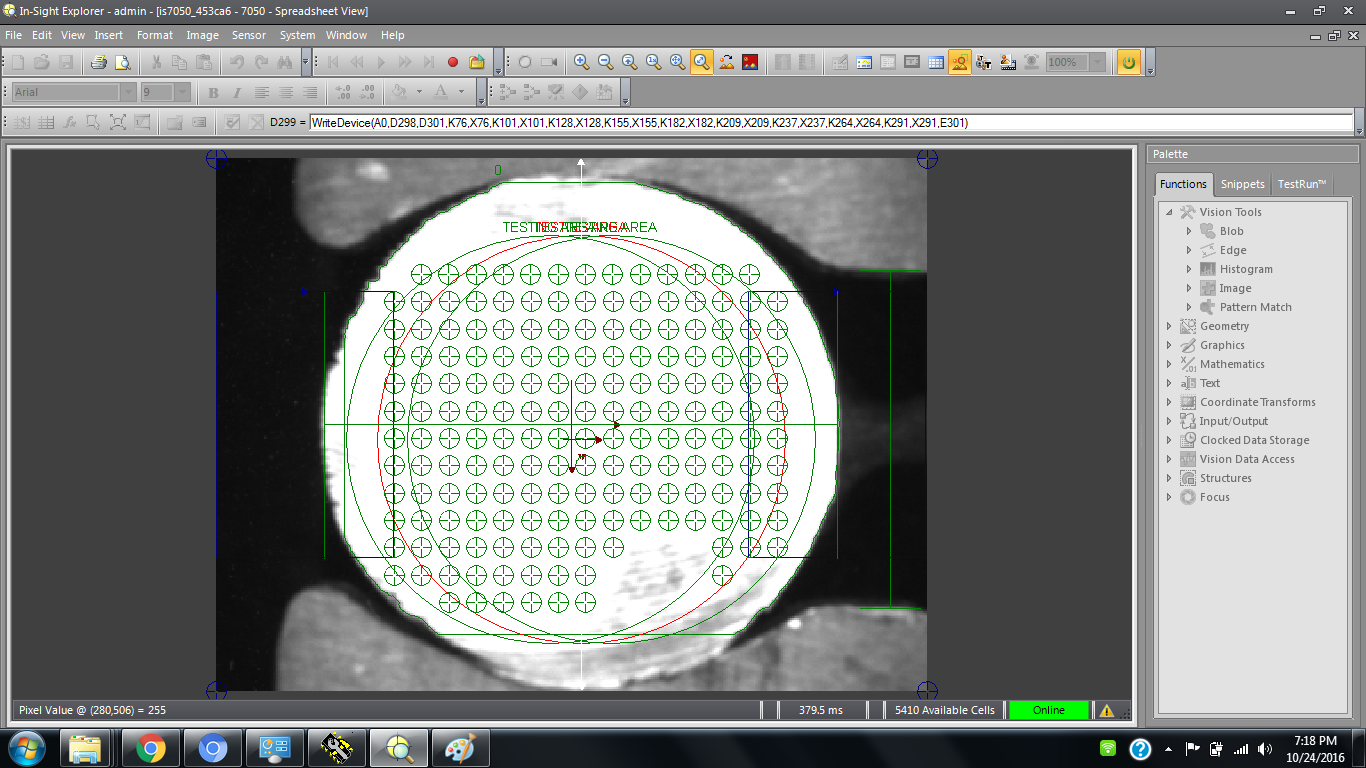

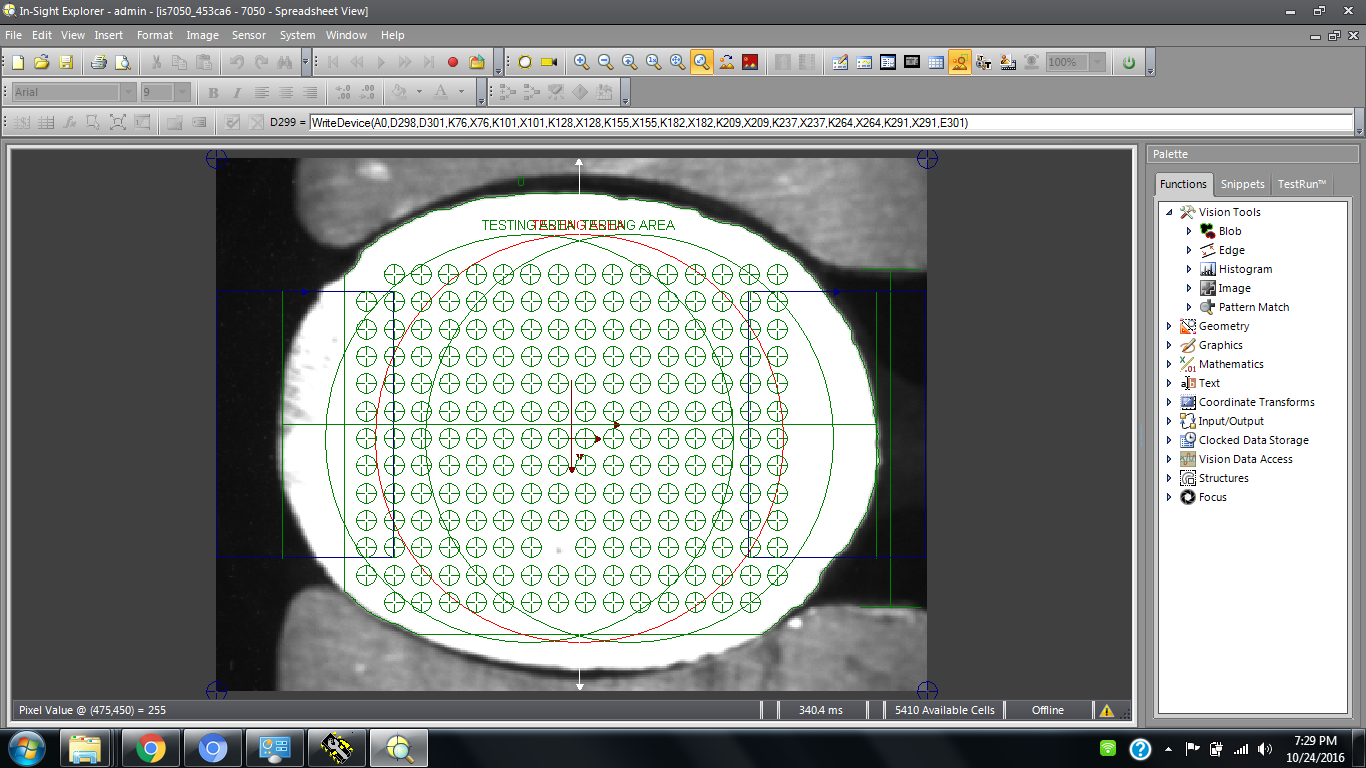

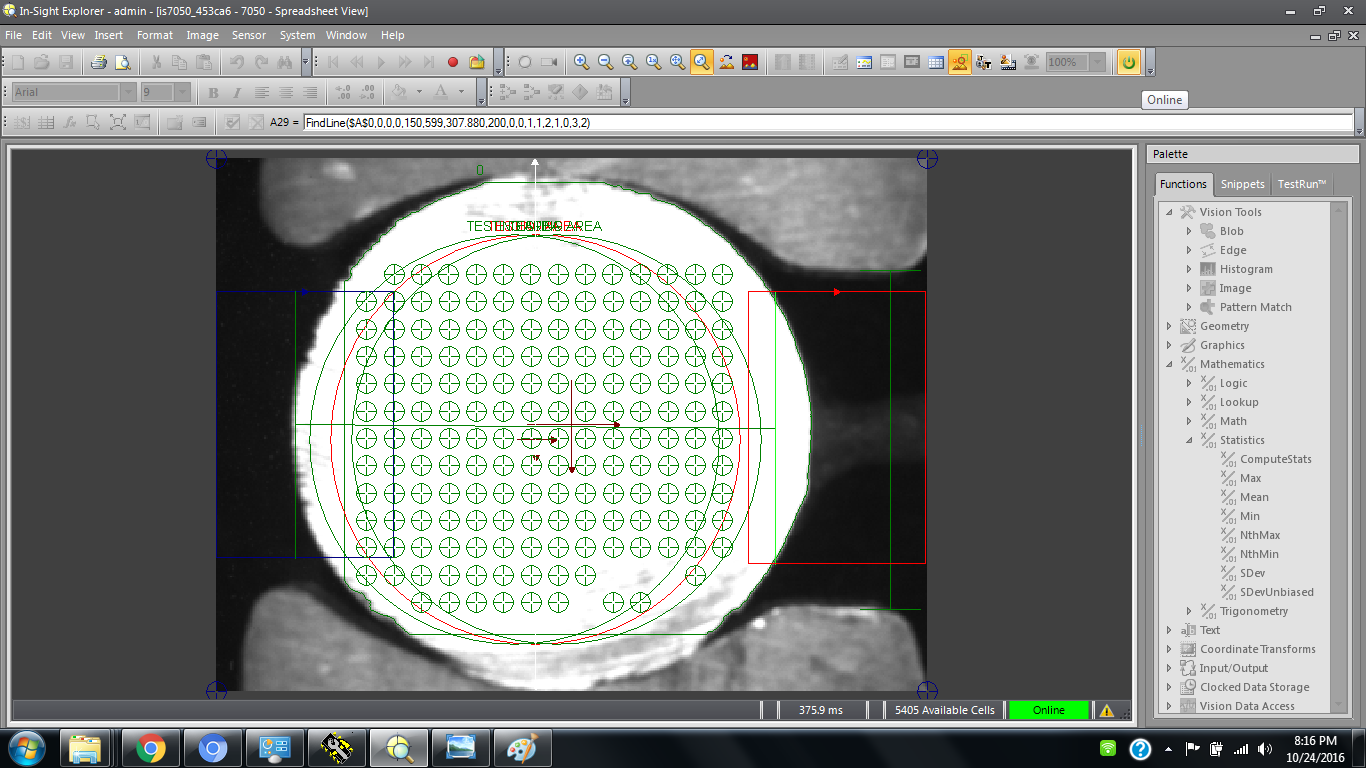

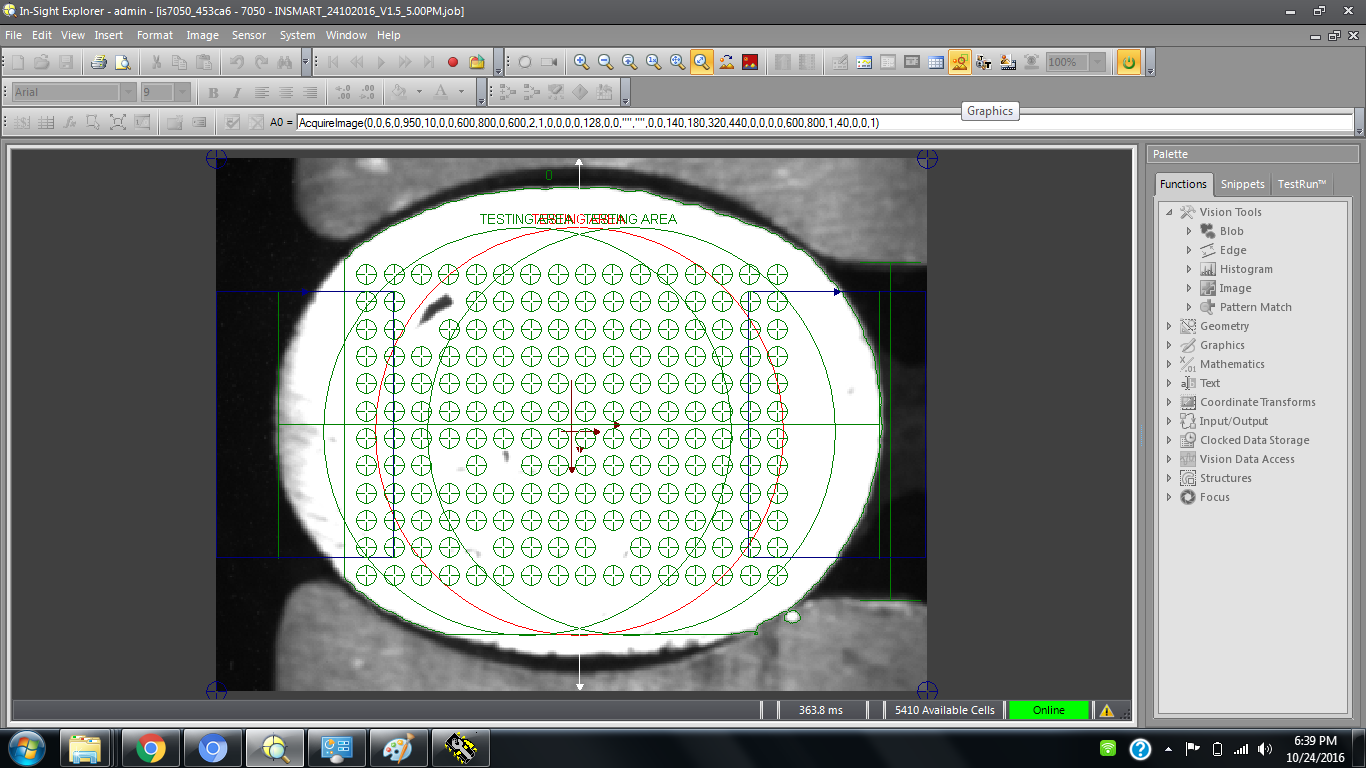

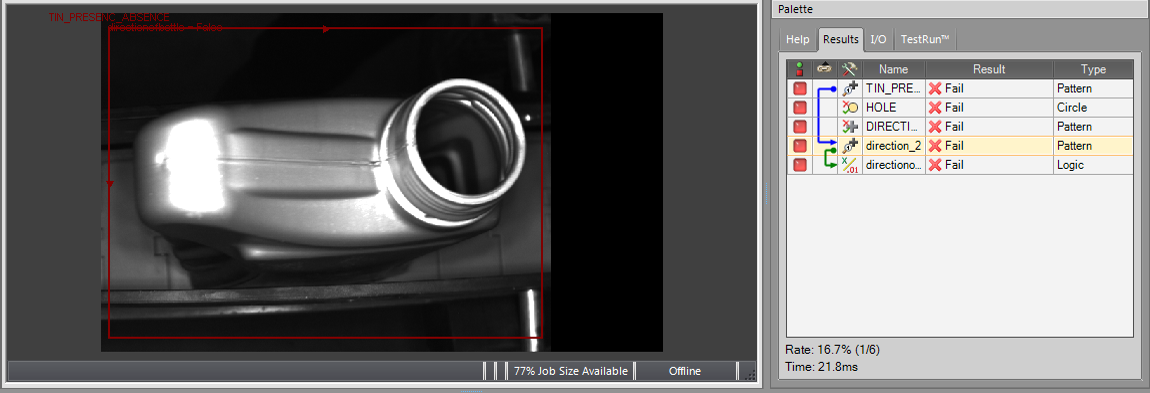

2DMax® with patent-pending PowerGrid™ technology decodes severely damaged or poorly marked 2-D matrix codes, and can even read 2-D codes without visible perimeters or quiet zones |

| 5 |

2DMax with PowerGrid overcomes variations in lighting, marking method, code quality, or surface finish — including damaged finder and clocking patterns and quiet zone violations |

| 6 |

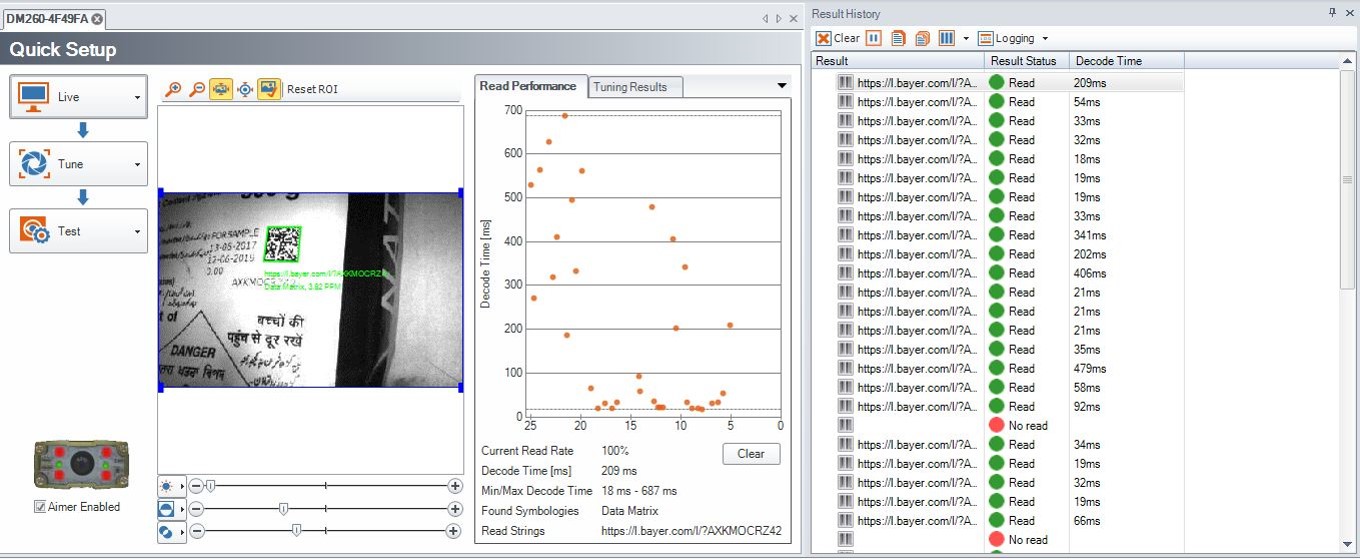

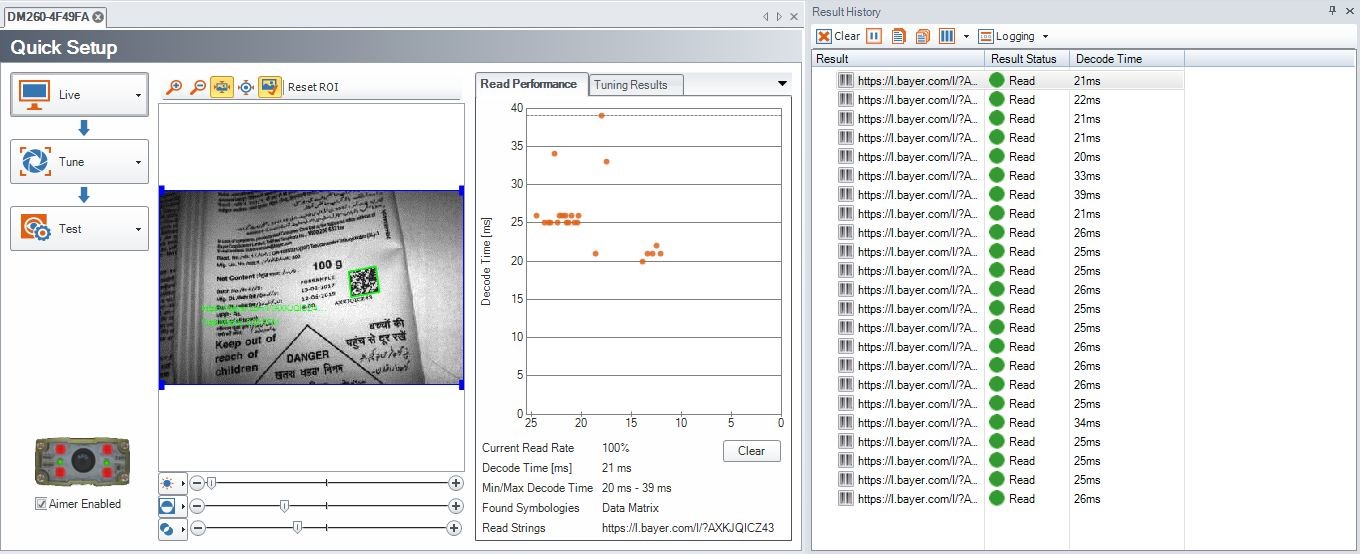

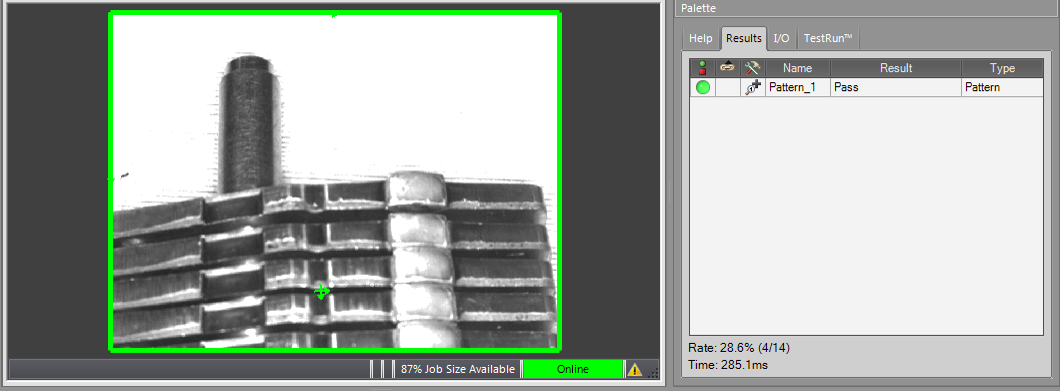

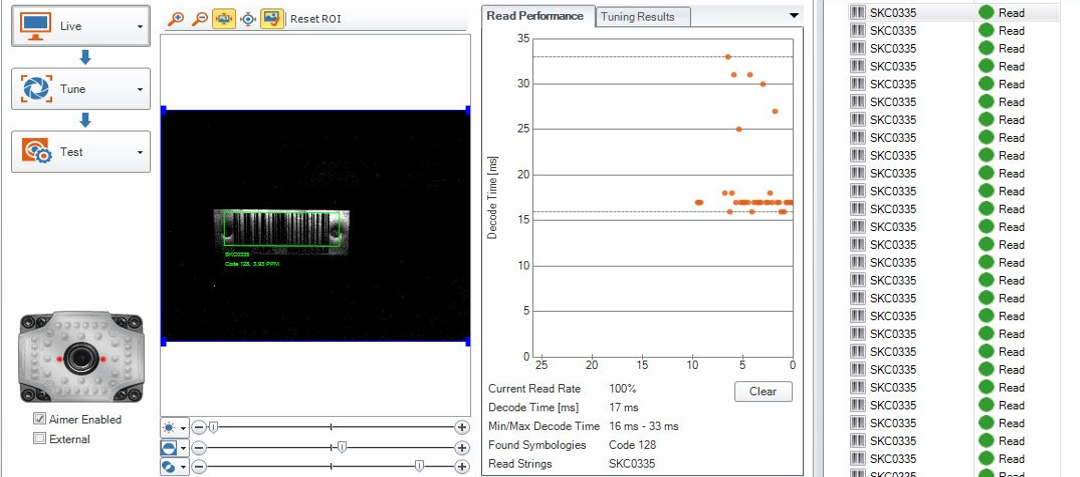

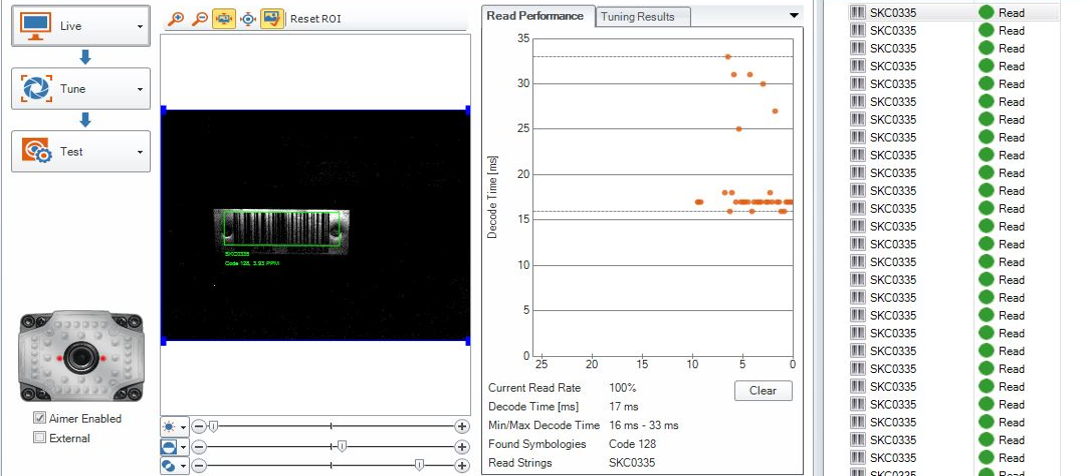

Intuitive Setup Tool for the simplest setup and deployment in real time |

| 7 |

Intelligent tuning technology automatically adjusts the settings of the integrated lighting to find the optimal light setup for the part |

| 8 |

Auto-tune and trigger buttons make the readers easy to set up without a PC or HMI |

| 9 |

1-D and 2-D quality metrics for process control monitoring and thresholding |

| 10 |

Various trigger modes (self, single, burst, etc.) to meet the broadest range of customer applications |

| 11 |

JavaScript programming for easiest PLC connection and integration on the factory floor |

Contact Detail's

Contact Detail's